2500+ diverse products

20+ years of professional experience in the hydraulic hammer industry

1000+ satisfied customers

2500+ diverse products

20+ years of professional experience in the hydraulic hammer industry

1000+ satisfied customers

2500+ diverse products

20+ years of professional experience in the hydraulic hammer industry

1000+ satisfied customers

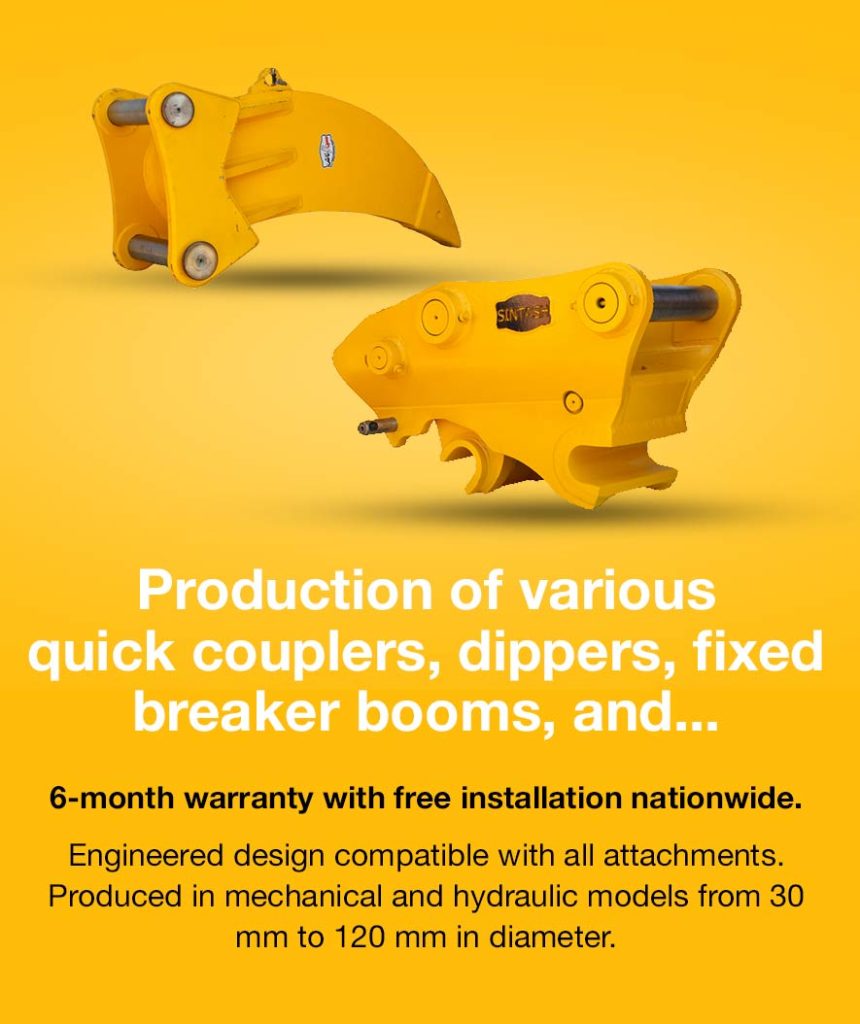

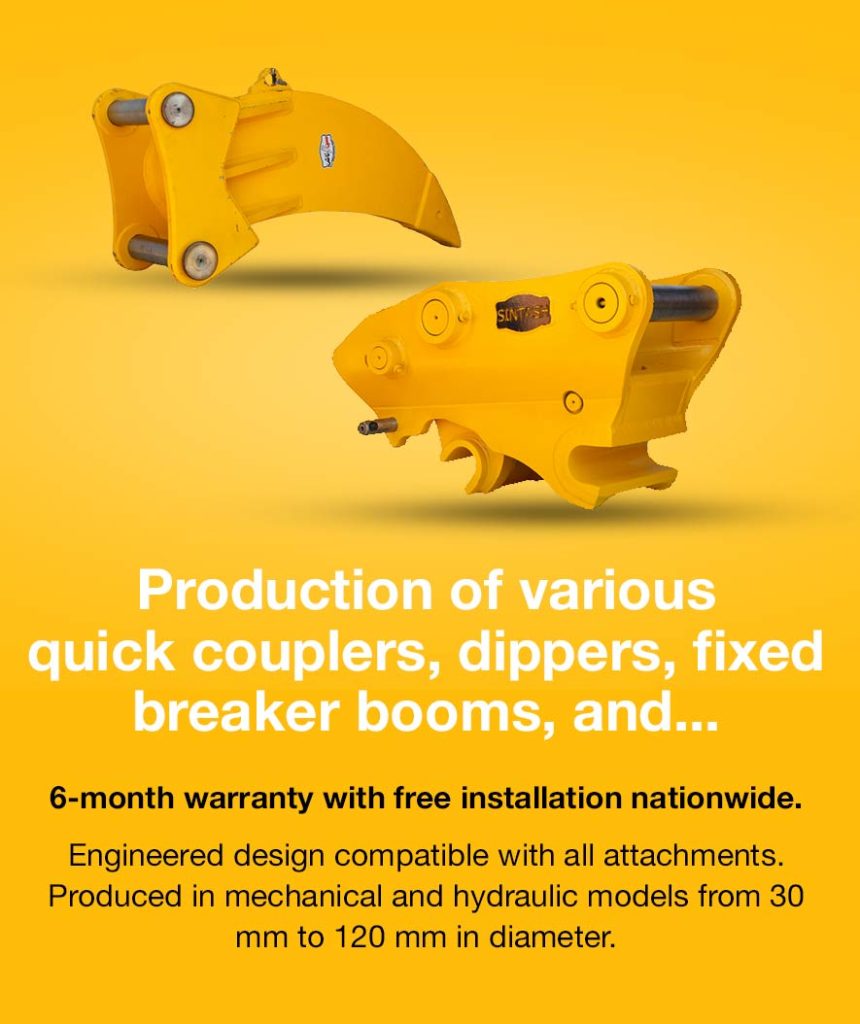

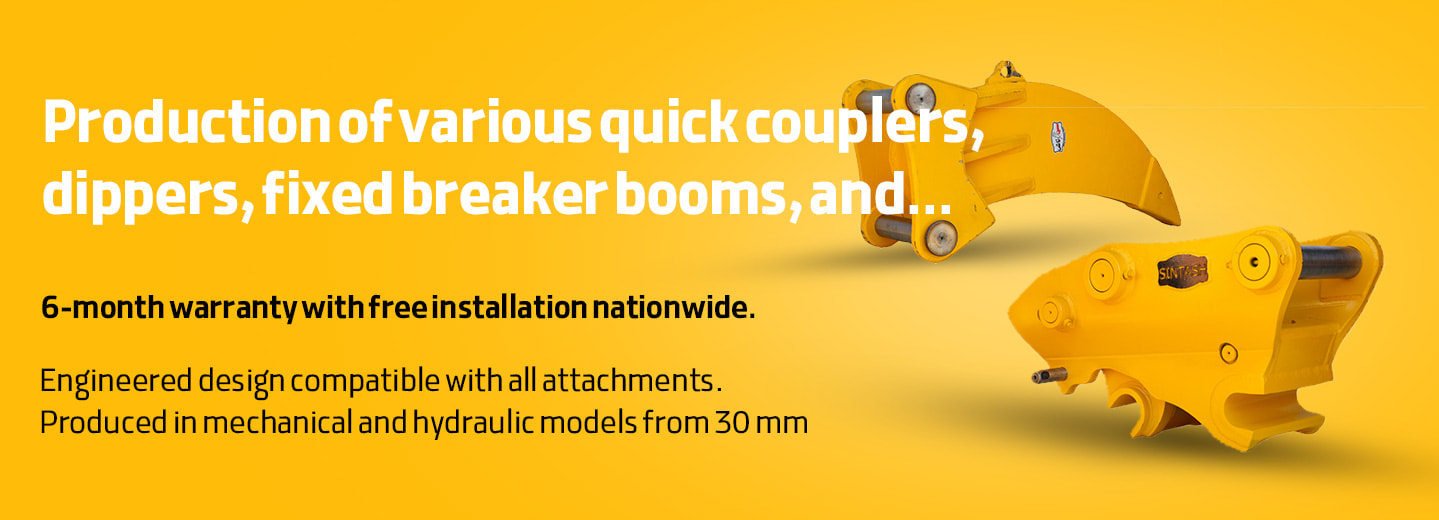

Manufactured Products

Product not found

Imported Products

Product not found

Services

Break-even welding services

Alloy steel cutting services

Forging, welding and rolling service hall

Boring services

CNC milling and horizontal center services

Rolling services

CNC turning services

Break-even welding services

Alloy steel cutting services

Forging, welding and rolling service hall

Boring services

CNC milling and horizontal center services

Rolling services

CNC turning services

Faq’s

What kind of company is Sintash Machine?

Sintash Machine is a leading manufacturer and supplier in the field of industrial machinery, especially hydraulic hammers and industrial presses, focusing on high quality, durability, and efficiency.

What are the main products of Sintash Machine?

The main products of Sintash Machine include various hydraulic hammers (such as the STM and MTB series, as well as Komatsu and Montabert models), industrial presses (such as the 400-ton press), and related spare parts.

What advantages distinguish working with Sintash Machine?

Sintash Machine offers products with long lifespan and optimal performance by utilizing up-to-date technical knowledge, using high-quality raw materials, implementing strict quality control throughout all production stages, and providing reliable after-sales services.

What is a hydraulic hammer and what is its use?

A hydraulic hammer is a powerful tool attached to heavy machinery like excavators, used for demolition of concrete, breaking rocks, asphalt cutting, trench digging, and various construction and civil engineering tasks.

What models of hydraulic hammers are available at Sintash Machine?

Sintash Machine offers a variety of hydraulic hammer models, including STM ST100, STM ST70, MTB 255, MTB 215, MTB 285, as well as Komatsu 150 and Montabert 501 (BRH 501) hammers.

What is the main difference between different models of hydraulic hammers (e.g., STM and MTB)?

The main differences lie in impact capacity, size, and weight, which affect compatibility with various excavator sizes and types of applications (ranging from light to heavy-duty work). Some models also have special features like noise reduction.

How can I choose the right hydraulic hammer for my excavator?

Choosing the right hammer depends on the weight and power of your excavator, the type of material to be demolished (concrete, rock, asphalt), and the workload. Sintash Machine experts can provide consultation to help you make the best choice.

Do Sintash Machine’s hydraulic hammers have noise reduction capabilities?

Yes, many models of Sintash Machine’s hydraulic hammers (especially those with silent covers) are designed to significantly reduce operational noise levels, making them suitable for use in urban and noise-sensitive areas.

How can the lifespan and performance of a hydraulic hammer be ensured?

Using high-quality raw materials, engineered design for maximum energy transfer, high resistance to wear and impact, along with regular maintenance and the use of original spare parts, guarantees the lifespan and performance of the hammer.

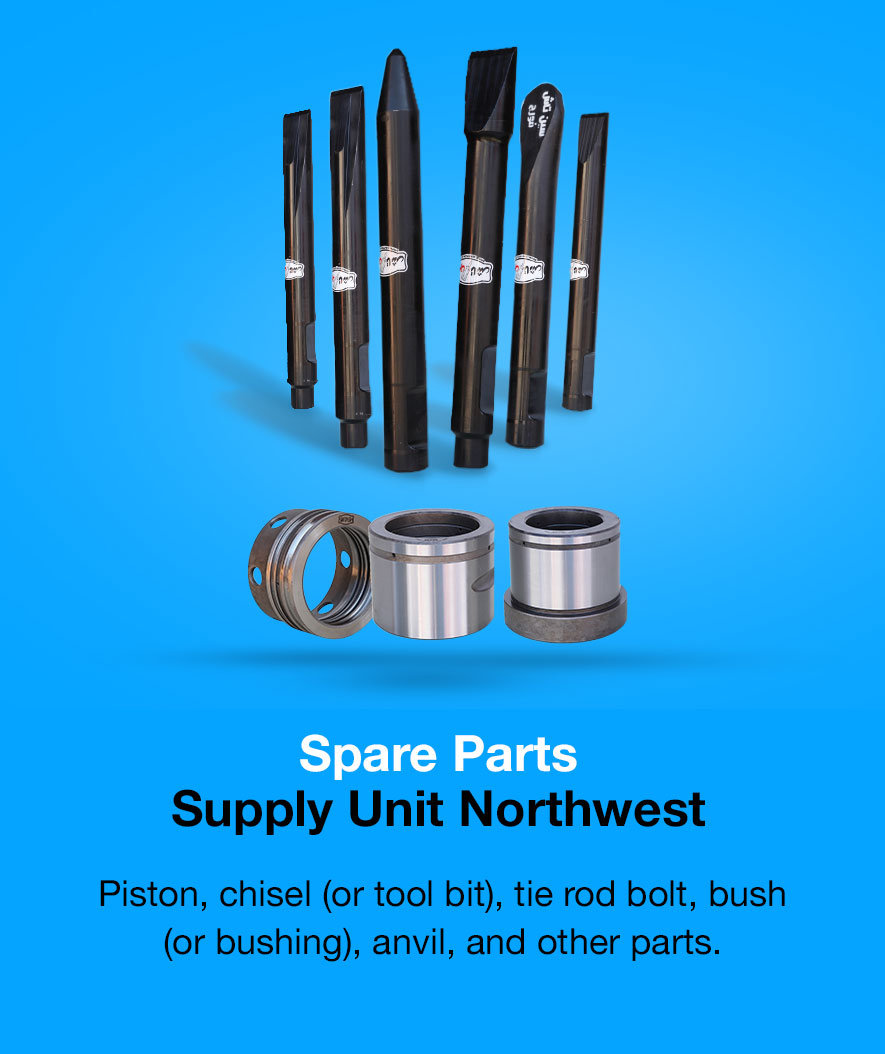

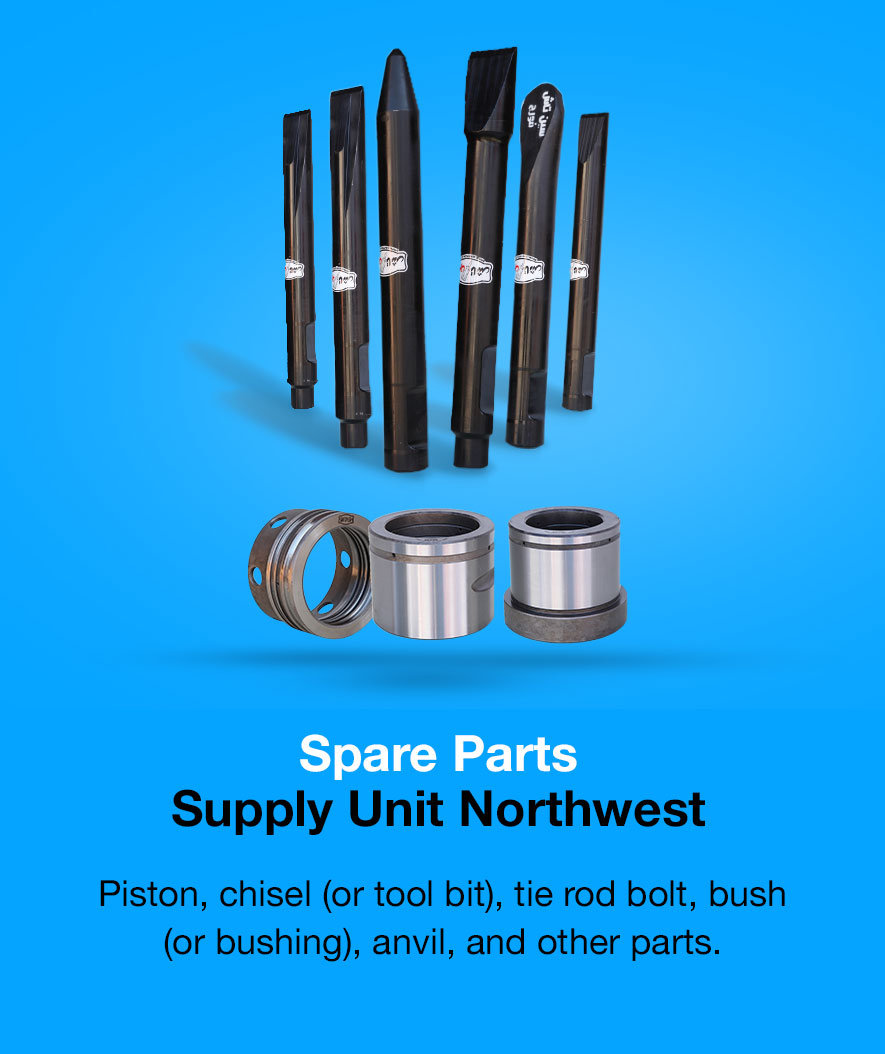

Does Sintash Machine also supply spare parts for hydraulic hammers?

Yes, Sintash Machine provides various spare and consumable parts for hydraulic hammers, such as chisels, bushings, seal kits, pistons, and more.

How is the installation and maintenance of hydraulic hammers?

Sintash Machine’s hydraulic hammers are designed for easy installation and maintenance. Easy access to service points and user-friendly design minimize downtime. The user manual and support team can guide you through the process.

What is an industrial press and what is its use?

An industrial press is a powerful machine used to shape, bend, cut, or assemble metal parts and other materials in various industries such as metalworking, automotive, and parts manufacturing.

What are the features of Sintash Machine’s 400-ton press?

The Sintash Machine 400-ton press has a force capacity of 400 tons, a very strong and stable body structure, an advanced hydraulic (or mechanical) system that allows precise control of parameters (speed, pressure, stroke length), and ease of maintenance.

Which industries is this press suitable for?

The 400-ton press is suitable for a wide range of heavy pressing operations in various industries, including automotive, parts manufacturing, and metalworking.

How does the Sintash industrial press machine help to increase production precision and quality?

Its advanced control system and the capability for precise adjustment of working parameters, combined with a robust and stable structure, enable the production of parts with high precision and quality.

Does Sintash machine offer after-sales services and technical support?

Yes, Sintash machine is committed to providing comprehensive after-sales services and technical support for all its products to ensure customer peace of mind.

How can I contact Sintash machine for a purchase or consultation?

You can contact us through the contact form on the website, the available phone numbers, or the email address.

How long is the warranty period for Sintash machine products?

The warranty period varies for each product and will be specified at the time of purchase or in the product’s technical specifications. Please, for details, with us

Does Sintash machine allow for product viewing?

For information on the possibility of viewing or product demonstrations, please contact our sales team.

What commitment does Sintash machine have regarding quality and customer satisfaction?

Sintash machine, by focusing on using the best raw materials, advanced production processes, and strict quality control, is committed to providing products with the highest standards and achieving complete customer satisfaction.

Sintash Machine is a leading manufacturer and supplier in the field of industrial machinery, especially hydraulic hammers and industrial presses, focusing on high quality, durability, and efficiency.

The main products of Sintash Machine include various hydraulic hammers (such as the STM and MTB series, as well as Komatsu and Montabert models), industrial presses (such as the 400-ton press), and related spare parts.

Sintash Machine offers products with long lifespan and optimal performance by utilizing up-to-date technical knowledge, using high-quality raw materials, implementing strict quality control throughout all production stages, and providing reliable after-sales services.

A hydraulic hammer is a powerful tool attached to heavy machinery like excavators, used for demolition of concrete, breaking rocks, asphalt cutting, trench digging, and various construction and civil engineering tasks.

Sintash Machine offers a variety of hydraulic hammer models, including STM ST100, STM ST70, MTB 255, MTB 215, MTB 285, as well as Komatsu 150 and Montabert 501 (BRH 501) hammers.

The main differences lie in impact capacity, size, and weight, which affect compatibility with various excavator sizes and types of applications (ranging from light to heavy-duty work). Some models also have special features like noise reduction.

Choosing the right hammer depends on the weight and power of your excavator, the type of material to be demolished (concrete, rock, asphalt), and the workload. Sintash Machine experts can provide consultation to help you make the best choice.

Yes, many models of Sintash Machine’s hydraulic hammers (especially those with silent covers) are designed to significantly reduce operational noise levels, making them suitable for use in urban and noise-sensitive areas.

Using high-quality raw materials, engineered design for maximum energy transfer, high resistance to wear and impact, along with regular maintenance and the use of original spare parts, guarantees the lifespan and performance of the hammer.

Yes, Sintash Machine provides various spare and consumable parts for hydraulic hammers, such as chisels, bushings, seal kits, pistons, and more.

Sintash Machine’s hydraulic hammers are designed for easy installation and maintenance. Easy access to service points and user-friendly design minimize downtime. The user manual and support team can guide you through the process.

An industrial press is a powerful machine used to shape, bend, cut, or assemble metal parts and other materials in various industries such as metalworking, automotive, and parts manufacturing.

The Sintash Machine 400-ton press has a force capacity of 400 tons, a very strong and stable body structure, an advanced hydraulic (or mechanical) system that allows precise control of parameters (speed, pressure, stroke length), and ease of maintenance.

The 400-ton press is suitable for a wide range of heavy pressing operations in various industries, including automotive, parts manufacturing, and metalworking.

Its advanced control system and the capability for precise adjustment of working parameters, combined with a robust and stable structure, enable the production of parts with high precision and quality.

Yes, Sintash machine is committed to providing comprehensive after-sales services and technical support for all its products to ensure customer peace of mind.

You can contact us through the contact form on the website, the available phone numbers, or the email address.

The warranty period varies for each product and will be specified at the time of purchase or in the product’s technical specifications. Please, for details, with us

For information on the possibility of viewing or product demonstrations, please contact our sales team.

Sintash machine, by focusing on using the best raw materials, advanced production processes, and strict quality control, is committed to providing products with the highest standards and achieving complete customer satisfaction.

Latest content

Working with Sintash Company was a pleasant experience for me. Their team is highly skilled, responsive, and committed to customer satisfaction. Their after-sales service is truly commendable. Thanks to Sintash Company.

Sina Ranjbar

Sintash Company was a successful experience for me. Working with this company is an honor. Their team is highly skilled, responsive, and committed to customer satisfaction.

Ata Vali

Working with Sintash Company was a pleasant experience for me. Their team is highly skilled, responsive, and committed to customer satisfaction. Their after-sales service is truly commendable. Thanks to Sintash Company.

Sina Rnajbar

Sintash Company was a successful experience for me. Working with this company is an honor. Their team is highly skilled, responsive, and committed to customer satisfaction.

Ata Vali