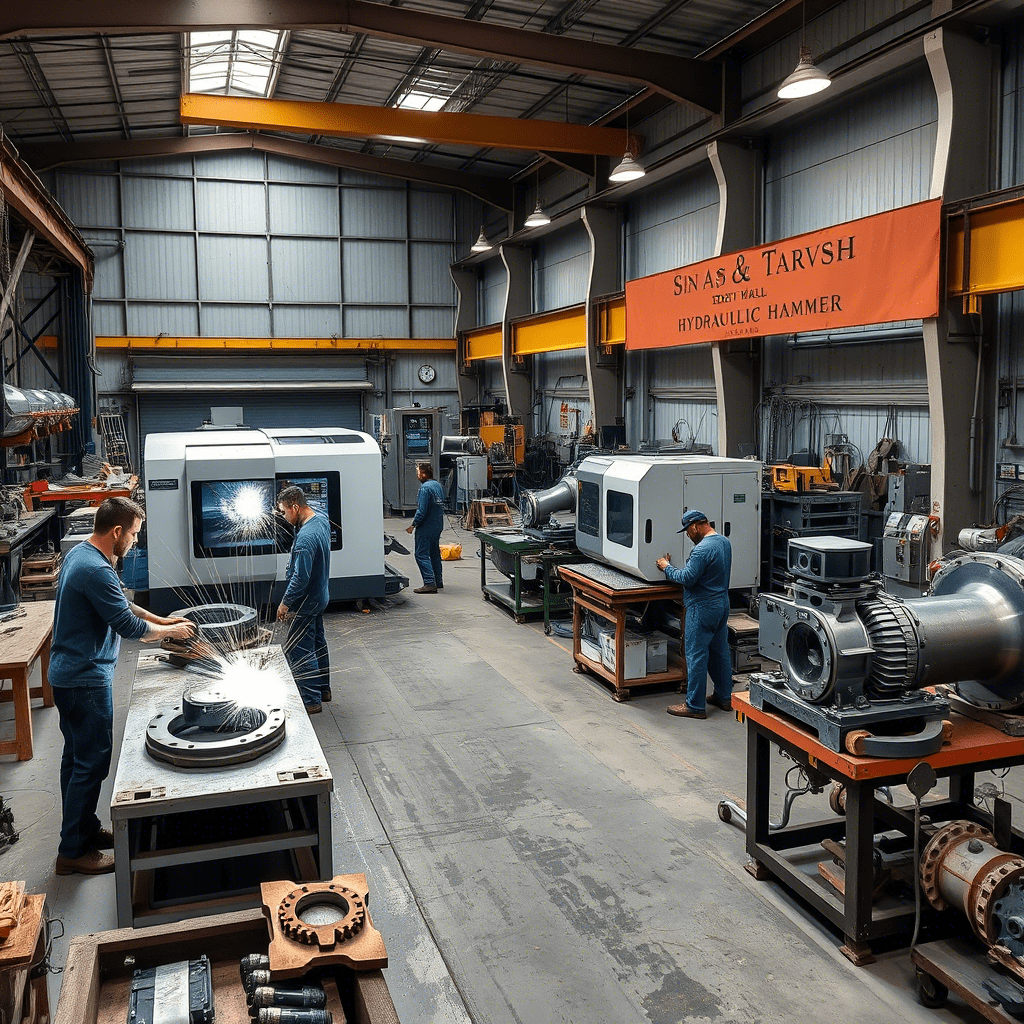

Sintash Machine, utilizing the technical knowledge and high expertise it has gained over the past 15 years in the field of manufacturing and repairing hydraulic hammers and industrial parts, has provided its customers with the service of “friction welding” or “butt welding” using an advanced and innovative device. This device, which was completely designed and manufactured by the company’s in-house expert and engineering team, is capable of welding all types of ordinary and alloy steels with a diameter of more than 80 mm with excellent quality and very high strength. This type of welding, which has greater strength and longer useful life compared to traditional methods, is especially widely used in the repair and reconstruction of heavy parts such as hydraulic bolts and connections of road construction, mining and industrial machines. With these services, Sintash Company, while improving the quality and durability of parts, helps its customers reduce the costs of replacing parts and increase the productivity of their machines. This service is an example of Sintash’s commitment to providing practical, modern solutions that comply with international standards.

In line with Sintash Machine’s long-term goal of fully localizing the production and reconstruction of heavy industrial parts, the “alloy steel cutting” service is provided as one of the main pillars in the production and repair chain of vital parts of industrial, mining and road construction machines. Using three fully automatic, precise and advanced cutting machines, Sintash Company is able to cut all types of ordinary and alloy steels up to a diameter of 500 mm and even more simultaneously and with high precision. This technical capacity not only helps to increase the efficiency and quality of manufactured parts, but also plays a prominent role in the overhaul and reconstruction of hydraulic hammers and other heavy machines. By utilizing these advanced machines and experienced specialists, Sintash Machine, while complying with global standards in metal cutting, minimizes the downtime of customers’ machines and increases their productivity. These services, along with other specialized services of this company, demonstrate Sintash’s special commitment to improving the quality, durability and efficiency of industrial equipment in the country.

Sintash Machine, using one of the most equipped and advanced forging, welding and rolling service halls in the domestic industry, performs all services related to shaping, cutting, bending, rolling and welding of metal parts with high technical standards and unparalleled accuracy. In this hall, precise cutting of sheets with the help of CNC machines, professional bending and rolling of metals, as well as complex and strength welding using modern technology and advanced devices are carried out by the company’s experienced engineers and specialists. These services are widely used in the manufacture of various quick coupler and ripper bodies and brackets, complete reconstruction of hydraulic hammer bodies, manufacture of sticks, masts and pockets of mechanical excavators, as well as repair and reinforcement of heavy industrial and mining parts. With a 15-year history and the company’s commitment to respecting consumer rights and providing high-quality and durable products and services, Sintash Forging Service Hall is an example of the combination of human skills and advanced technology, offering its customers practical, cost-effective and standard solutions. This service unit plays a key role in the production chain, repair and reconstruction of heavy components and is one of the main elements in realizing Sintash’s goal of achieving self-sufficiency in the hydraulic hammer and its ancillary equipment industry.

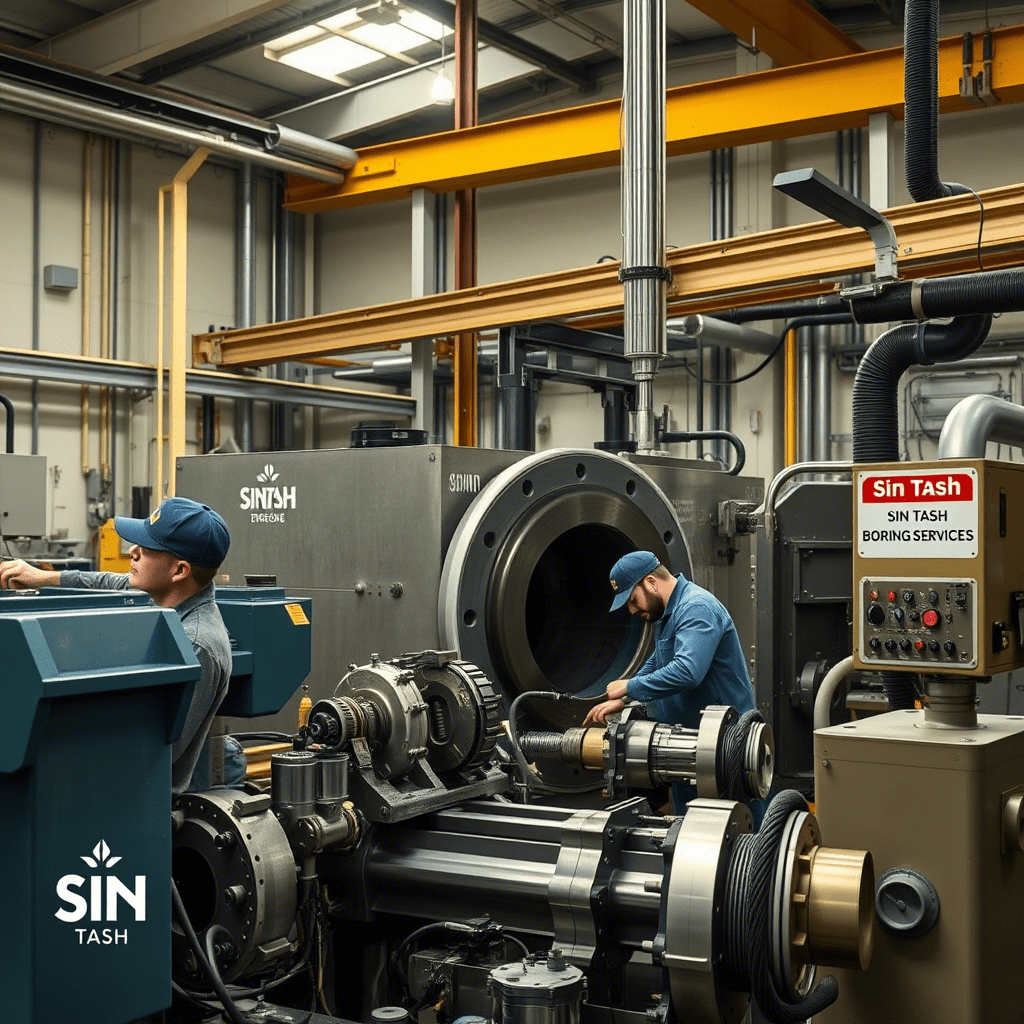

In heavy industries such as mining, road construction and industrial, precision in the production and repair of large and heavy parts is of great importance. Sintash Machine Company, with the benefit of advanced equipment and expert personnel, provides high-precision boring services for parts with high weight, diameter and volume. This process, which includes expanding, smoothing and precise grinding of internal holes of metal parts, plays an important role in the reconstruction and standardization of parts such as hydraulic hammer bodies, cylinders, axes and large industrial connections. Using specialized boring machines and an experienced team of engineers and technical technicians, Sintash ensures complete dimensional and mechanical compliance of parts with the required standards, while also increasing the useful life and better performance of customers’ devices. This service, along with other specialized forging, welding and repair services, demonstrates the company’s commitment to providing comprehensive, quality and cost-effective solutions for customers across the country.

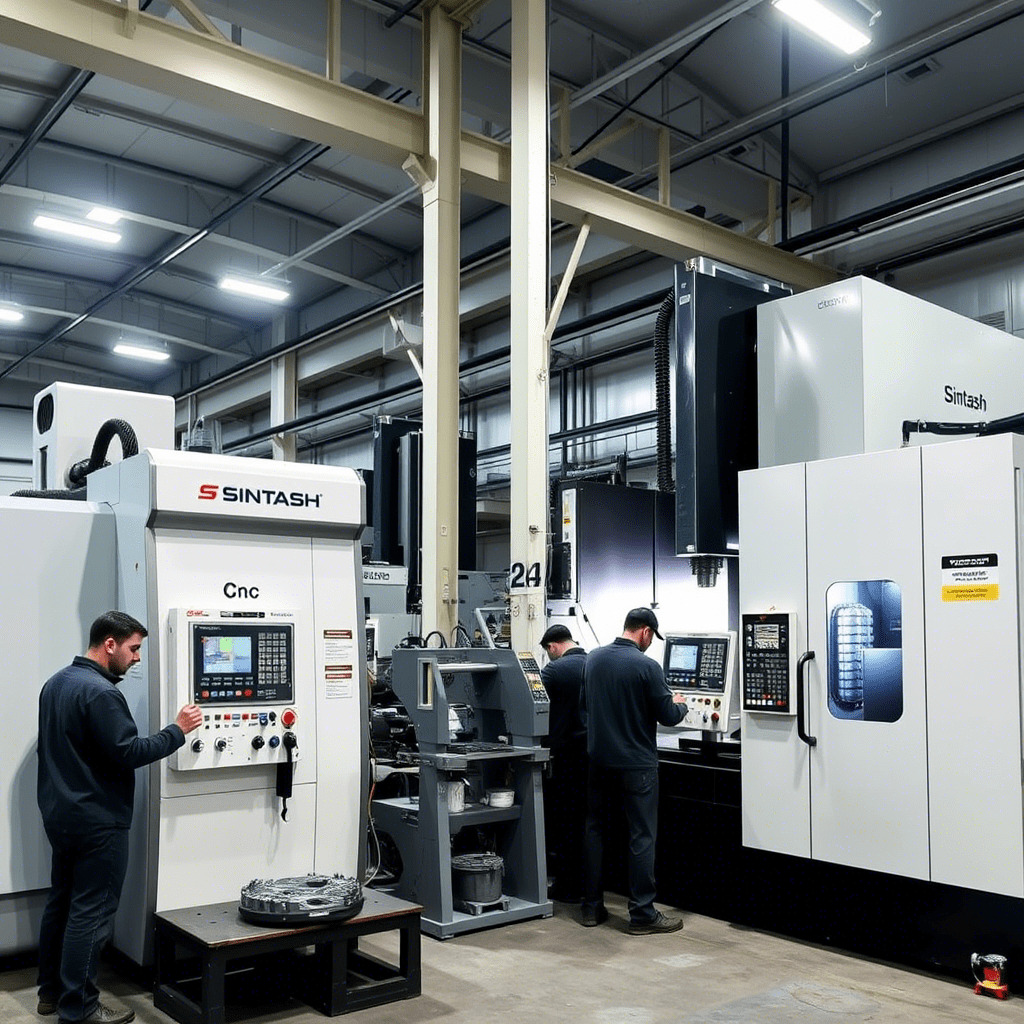

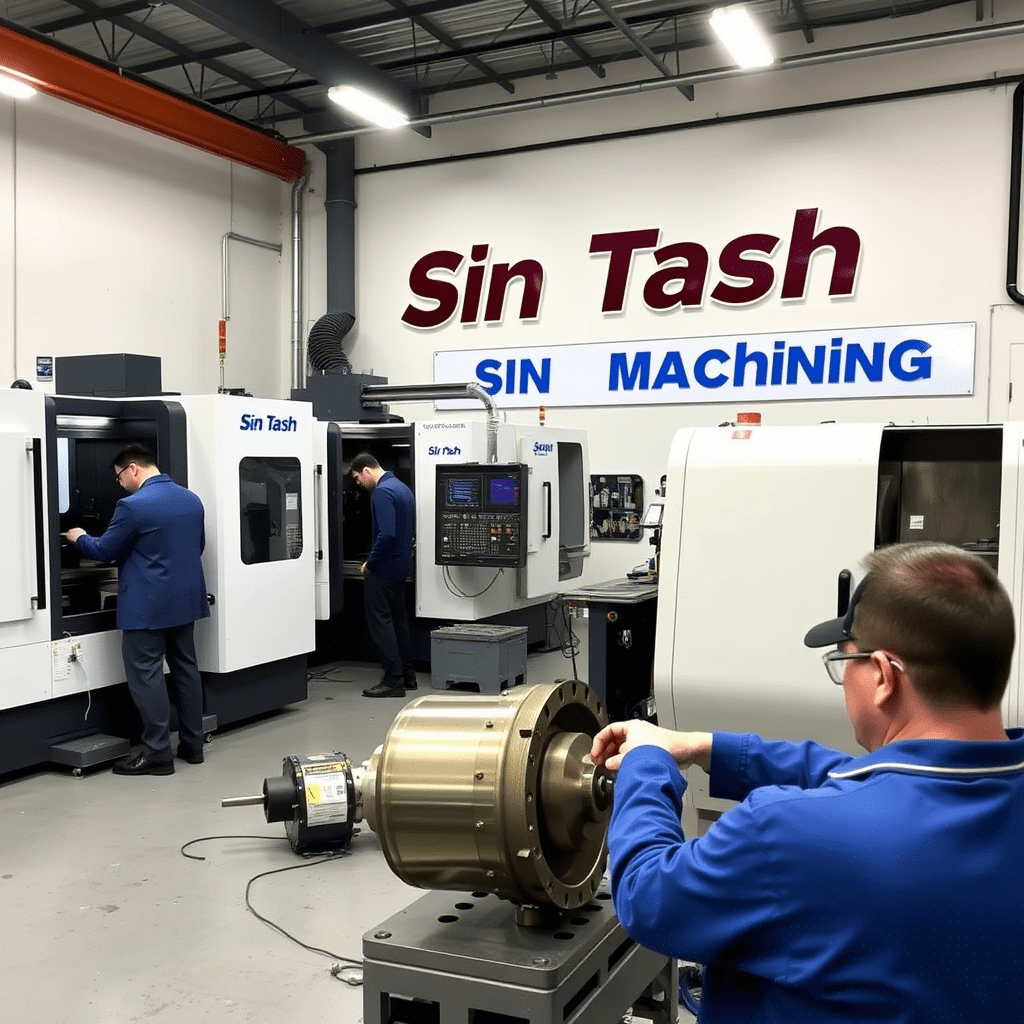

In the field of manufacturing and repairing industrial parts, high precision and compliance with precise mechanical standards are of great importance. Sintash Machine Company, as one of the leading manufacturing and repair units in the hydraulic hammer industry, provides CNC milling services (horizontal and vertical) using modern and fully controlled machinery to process various parts. These services include working on small and sensitive parts to large, heavy and complex parts used in the manufacture and repair of hydraulic hammers, booms, rippers and other road construction, mining and industrial machinery. Using CNC machines and experienced specialists, all milling operations are performed with micron accuracy and according to standard technical drawings. This technical capacity not only helps to increase the quality and durability of manufactured parts, but also ensures the optimal performance of the machinery during reconstruction and major repairs. Sintash’s milling services, covering a variety of parts and industrial needs, are an example of the company’s commitment to meeting international standards, achieving technical self-sufficiency, and providing comprehensive and sustainable services domestically.

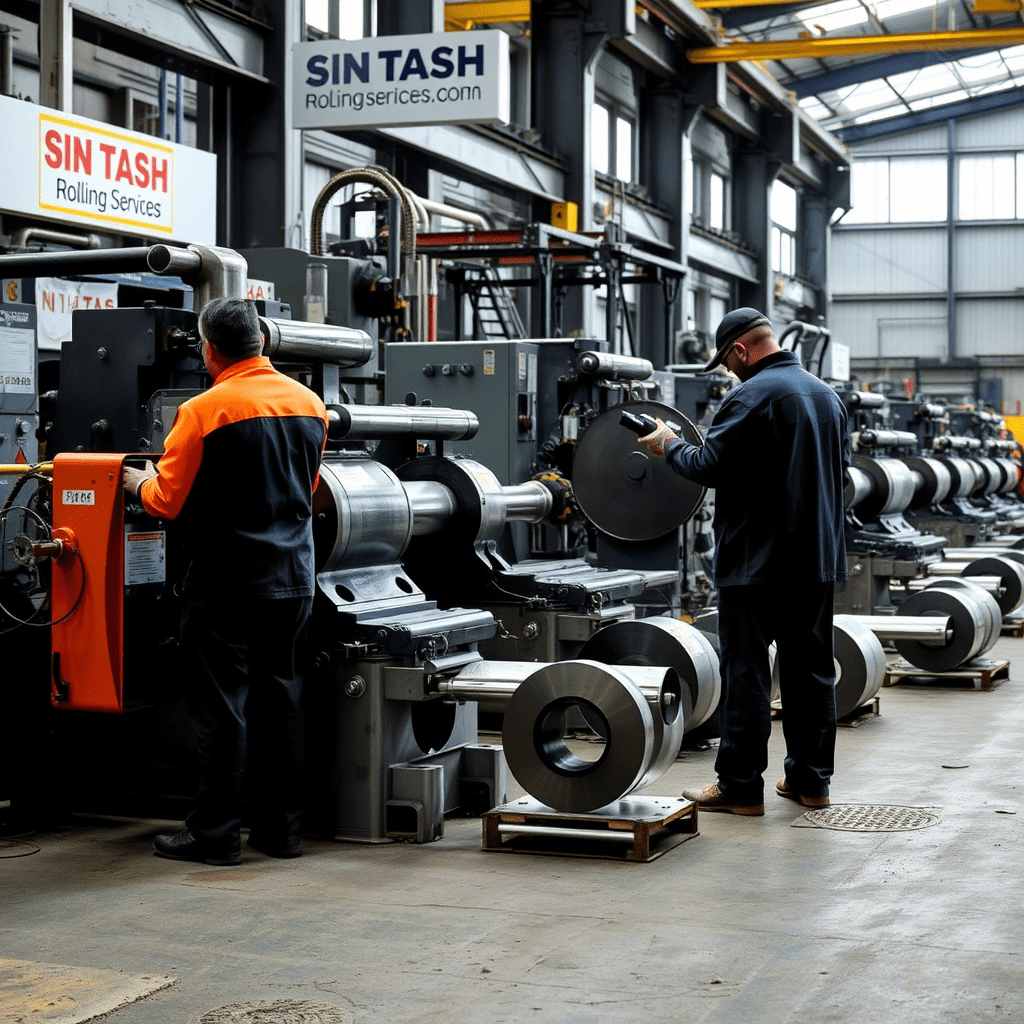

In the heavy mechanical parts manufacturing and repair industry, especially in the field of hydraulic hammers and road construction and mining machinery, the quality and strength of bolted connections play a significant role in the durability and safety of all systems. Sintash Machine Company, using the Spanish SENW rolling machine, one of the most advanced and powerful machines available in this field with a pressure capacity of 700 tons, offers rolling services for all types of alloy steels up to 80 mm in diameter. This advanced technology allows for the creation of threads (threads) on steel surfaces through a plastic metal forming process without chip removal. This method increases the tensile strength and fatigue resistance of the part by about 50% compared to traditional methods such as turning, and at the same time significantly improves the useful life of the bolts and connections. This service plays a key role in increasing the safety and long-term performance of the machines, especially in the production of Tapered Thread bolts used in hydraulic hammers and other critical parts. With this high capacity and technical precision, Sintash Machine has once again shown how, by investing in advanced equipment and developing internal technical knowledge, it can become one of the strongest national brands in the industrial parts supply chain.

In the production and repair chain of industrial parts, especially in the hydraulic hammers and heavy road construction, mining and industrial machinery sectors, high precision, excellent surface quality and compliance with strict technical standards are of great importance. Sintash Machine Company, using one of the most advanced, diverse and up-to-date CNC production and machining lines in the country, offers CNC turning services for various metal parts. These services include the production and processing of hydraulic hammers and other machinery parts in all sizes – from light to super heavy (weighing more than one ton) – with micron accuracy and in the shortest possible time. This technical capacity allows the company to meet domestic and industrial needs without dependence on imports and with competitive domestic quality. Using this capability, Sintash, while improving the strength and accuracy of the parts, offers its customers products with longer useful life and better performance. This service, along with other specialized forging, welding, cutting, and rolling services, is a testament to the company’s commitment to fully localizing industrial technologies and creating a strong and independent infrastructure in the domestic industry.

Manufacturer of hydraulic hammers and related parts, quick couplers and rippers, parts for road construction, mining, industrial machinery, etc.

Tabriz, Old Tabriz Road, 3 km from the Middle Road Police Station

Opposite the cut, next to the Rund Factory

Manufacturer of hydraulic hammers and related parts, quick couplers and rippers, parts for road construction, mining, industrial machinery, etc.