In drilling and demolition machinery, the quality and precision of connecting and power-transmitting components play a vital role in the overall performance, safety, and longevity of the equipment. Aware of this importance, Sintash Machine offers a range of high-quality, engineered couplings and shanks to ensure the optimal performance of your machinery.

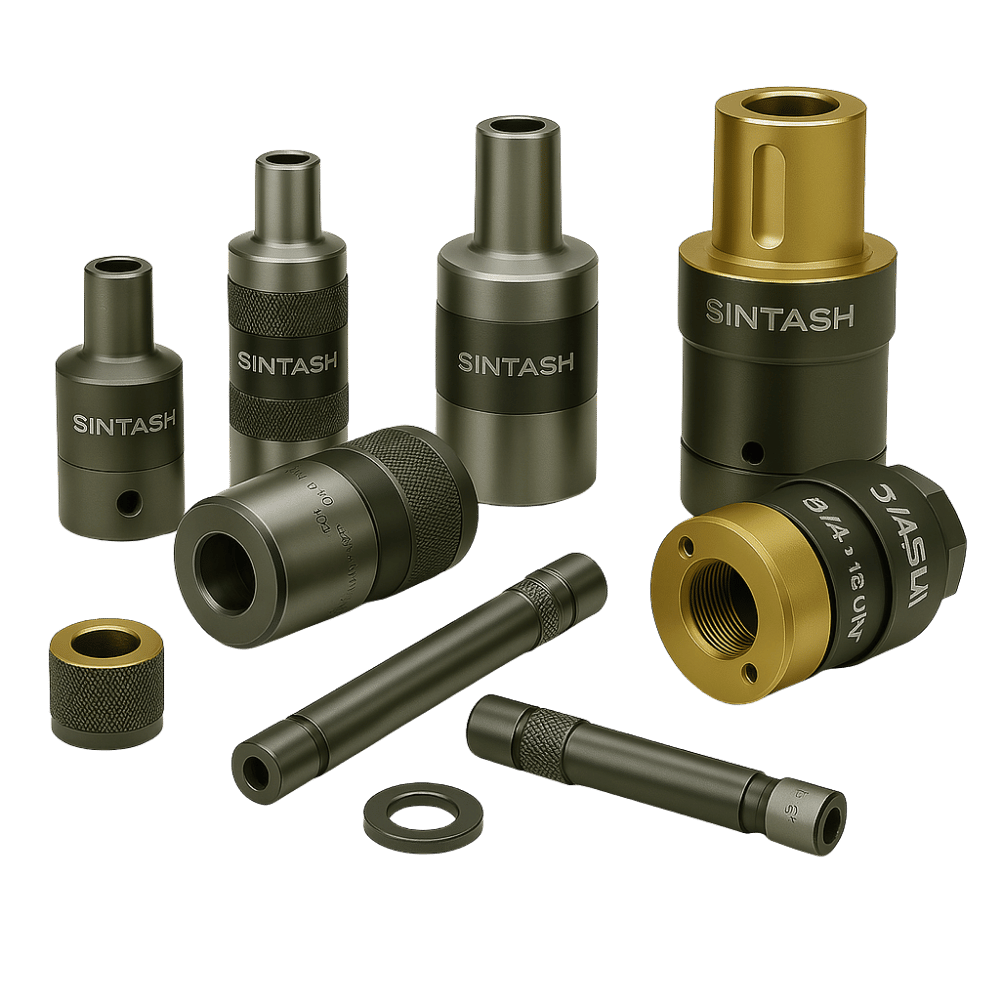

Sintash Machine Couplings:

Couplings in the hydraulic and pneumatic systems of drilling machinery and hydraulic hammers are responsible for the secure and leak-free connection of hoses and pipes. Couplings offered by Sintash Machine are manufactured from a-Test raw materials and adhere to the highest production standards to exhibit exceptional resistance to high working pressures, vibrations, and harsh environmental conditions. These couplings include various types such as Quick Couplings for easy and rapid connection and disconnection, as well as high-reliability fixed connections for more permanent applications. Using Sintash Machine couplings means ensuring a stable connection, preventing energy and fluid loss, and enhancing worksite safety.

Key Features of Sintash Machine Couplings:

- Premium Quality Materials: High resistance to corrosion, wear, and pressure.

- Precision Design: Perfect sealing and prevention of any leakage.

- Variety in Type and Size: Suitable for the needs of various equipment and hoses.

- Ease of Use: Especially in quick coupling models.

- Increased Lifespan of Hoses and Other Hydraulic System Components.

Sintash Machine Shanks/Shank Adapters:

The shank (or shank adapter) in top hammer drilling systems and some demolition hammers is a key component that transmits impact energy and rotation from the drifter or hammer to the drill rod and then to the bit. Sintash Machine shanks are produced using special alloy steels and undergo precise heat treatment processes to achieve maximum resistance to torsional and impact stresses, as well as wear. The precise design of the thread profile and contact surfaces in these shanks ensures optimal energy transfer, reduced wear on rods and bits, and straight, efficient drilling. Selecting a suitable, high-quality shank from Sintash Machine means increasing drilling efficiency, reducing the likelihood of breakage, and extending the overall life of the drill string.

Key Features of Sintash Machine Shanks:

- High-Strength Alloy Steel: Exceptional resistance to impact, fatigue, and wear.

- Precise Heat Treatment: To achieve optimal hardness and toughness.

- Precision Machining of Threads and Surfaces: Ensuring perfect fit and effective energy transfer.

- Variety for Different Drifters and Drilling Systems.

- Increased Lifespan of Other Drill String Components (Rods and Bits).

By choosing Sintash Machine couplings and shanks, you ensure quality, durability, and unparalleled performance, maximizing the productivity of your machinery. Our experts are ready to provide consultation for selecting the best parts suited to your equipment and needs.

Reviews

There are no reviews yet.