Sintash Machine, leveraging advanced technical knowledge and years of experience in manufacturing precise industrial components, produces and supplies a wide range of axial components for various machinery and equipment. Axial components are vital parts in any mechanical system, responsible for transmitting power, torque, or providing a fixed or moving axis for the rotation or linear movement of other parts. The quality, dimensional accuracy, and mechanical properties of these components directly impact the efficiency, lifespan, and safety of the entire system.

Utilizing premium raw materials, including alloy steels, high-quality carbon steels, and other engineering metals, and employing advanced manufacturing processes such as precision CNC machining, grinding, specialized heat treatments (like hardening, tempering, and induction hardening), and surface coatings (such as hard chrome plating, galvanizing, and phosphating), Sintash Machine manufactures axial components to the highest standards.

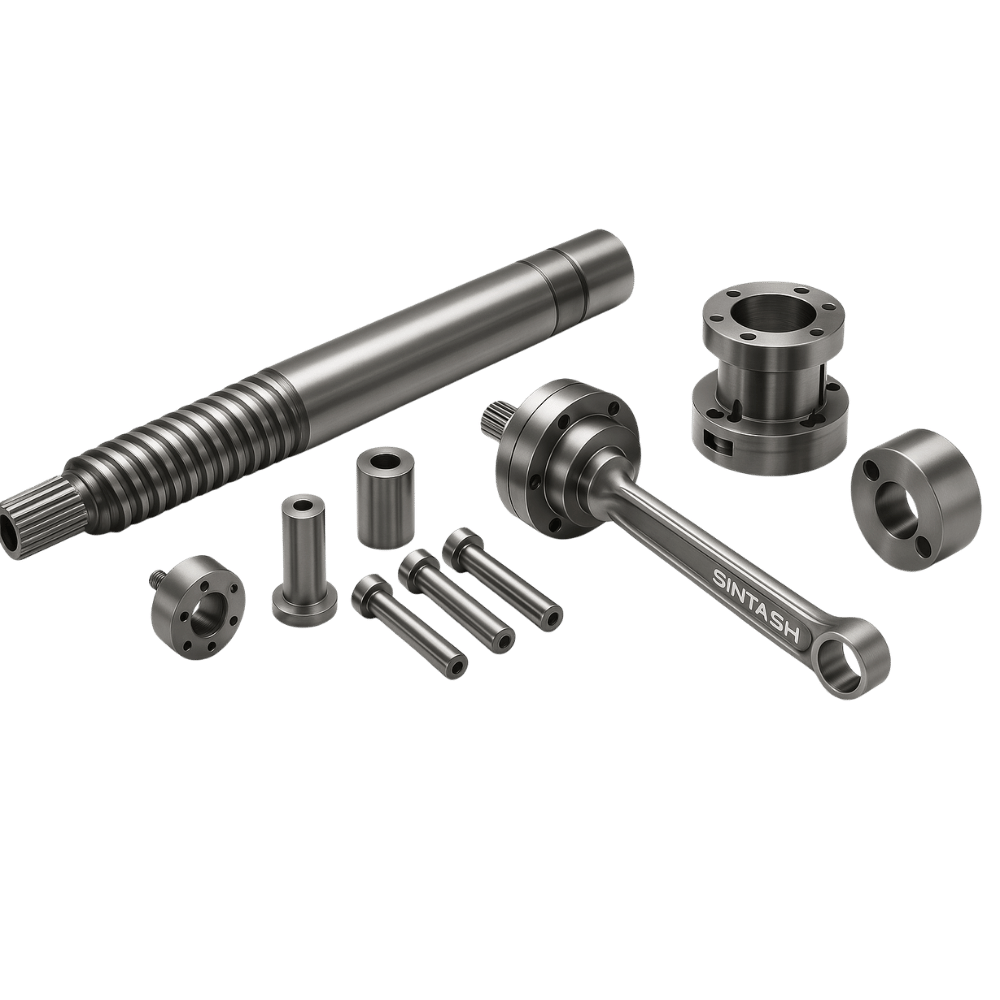

Some types of axial components manufacturable by Sintash Machine include:

- Various Shafts: Including power transmission shafts, gearbox input and output shafts, splined shafts, flexible shafts, and shafts used in hydraulic and electric pumps and motors. These shafts are designed and built to withstand torsional, bending, and axial loads.

- Various Axles: For mobile machinery, trailers, and industrial equipment requiring wheel axles. Sintash Machine axles are produced with high load-bearing capacity and fatigue resistance.

- Various Pins: Including pivot pins, locking pins, guide pins, and pins used in the joints of heavy machinery such as excavators, loaders, and cranes. These pins are made from wear and shear-resistant materials.

- Various Piston Rods: For hydraulic and pneumatic cylinders, with a highly polished and corrosion-resistant surface (often hard chrome plated) to ensure perfect sealing and smooth movement.

- Spindles: For machine tools and equipment requiring precise, high-speed rotation.

- Axial Bushings and Sleeve Bearings: To reduce friction and guide the rotational or linear movement of shafts.

Sintash Machine’s engineering team is ready to collaborate with various industries to design and manufacture custom axial components based on precise customer requirements and technical specifications. Comprehensive quality control at all stages, from raw material selection to final product inspection, guarantees the delivery of flawless components with reliable performance.

Key Features of Sintash Machine Axial Components:

- High dimensional accuracy and very precise machining tolerances.

- Use of premium raw materials with quality certification.

- Optimized heat treatment to achieve the best mechanical properties (hardness, toughness, wear resistance).

- Corrosion and wear-resistant surface coatings.

- Custom manufacturing capability based on drawings or samples.

- High resistance to static and dynamic loads.

- Long service life and reduced need for repairs and maintenance.

Ensure smooth, stable, and reliable performance of your equipment by choosing axial components from Sintash Machine.

Reviews

There are no reviews yet.