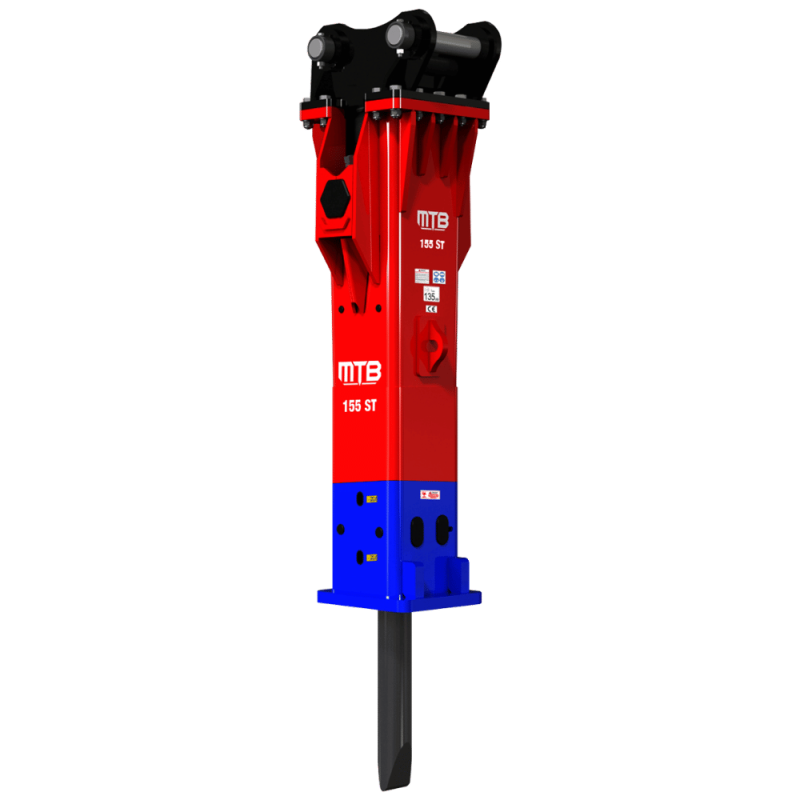

At the heart of every hydraulic hammer (breaker) lie precise and durable components that ensure the machine’s powerful and continuous operation. Among these, the cylinder and anvil of hydraulic hammers are two fundamental and vital parts responsible for guiding the piston and transferring the final impact energy to the tool, respectively. A proper understanding of the structure, function, and importance of these two components is essential for optimal use and correct maintenance of a hydraulic hammer.

Part 1: The Hydraulic Hammer Cylinder

-

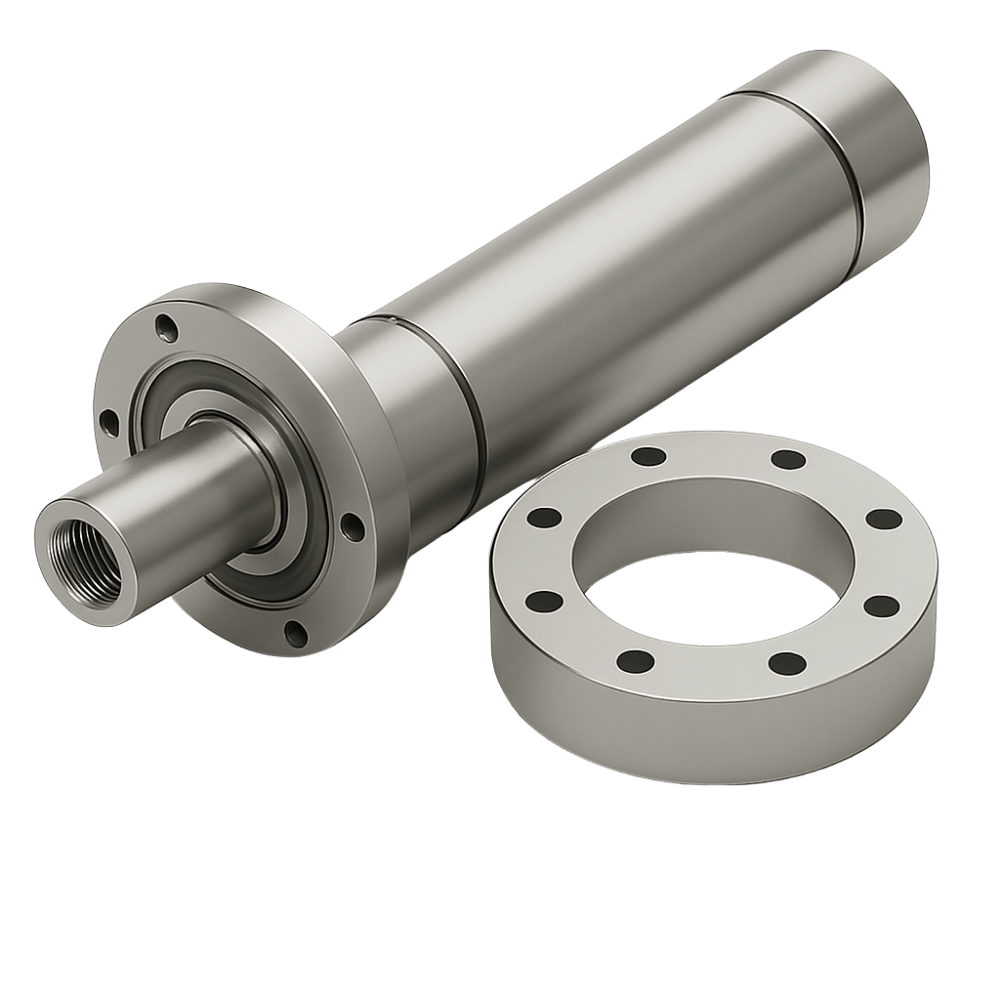

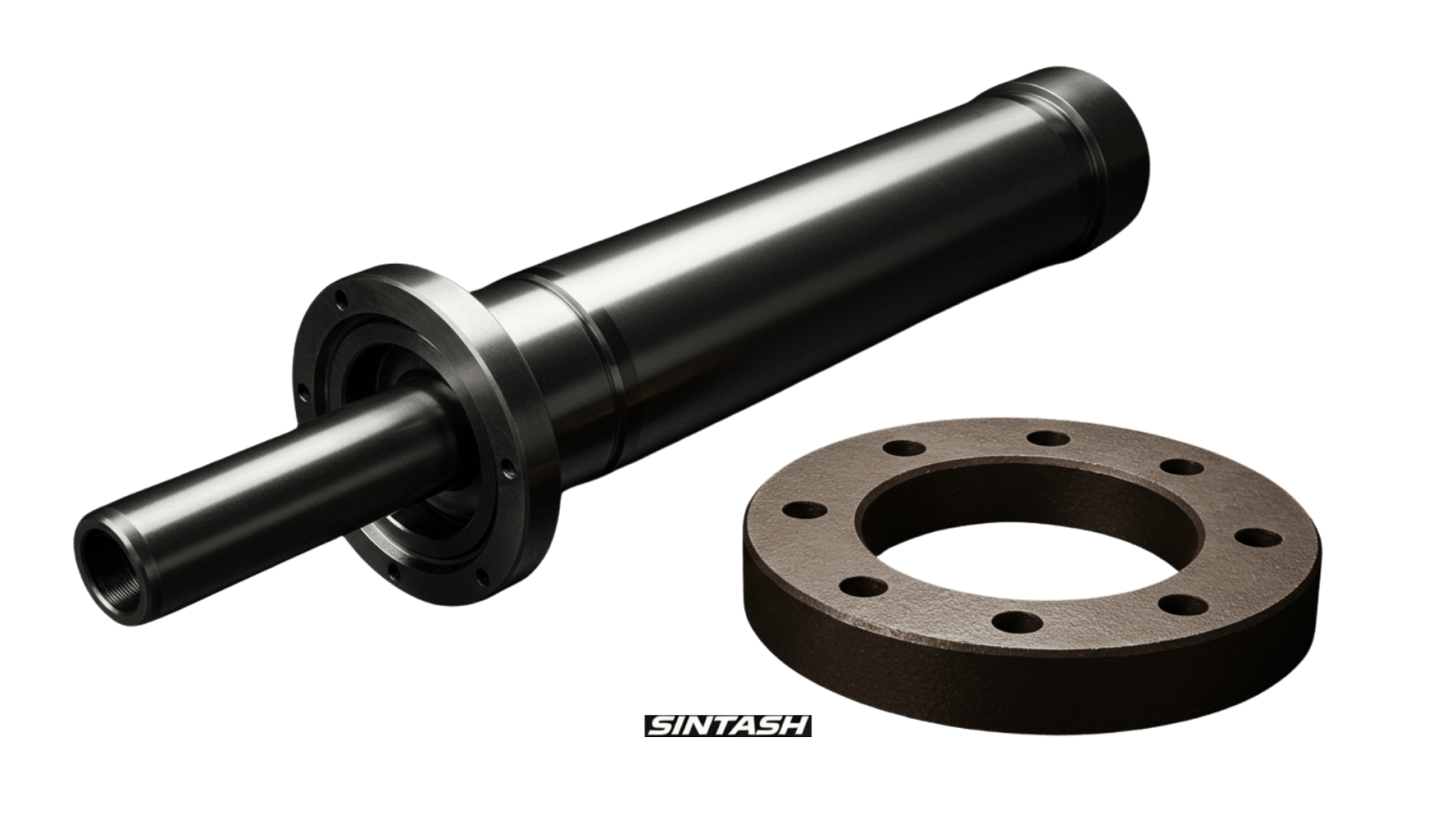

What is a Hydraulic Hammer Cylinder and its Role? The hydraulic hammer cylinder is the main cylindrical housing in which the hammer piston performs its high-speed, high-power reciprocating motion. This component not only defines the piston’s path of travel but must also withstand the high pressure of the hydraulic oil that drives the piston. The manufacturing quality and dimensional accuracy of the cylinder directly impact the hammer’s efficiency, power, and lifespan.

-

Structural Features and Materials in the Cylinder Hydraulic hammer cylinders are typically made from very high-strength alloy steels capable of withstanding dynamic pressures and fatigue from millions of impacts. The inner surface of the cylinder is honed and finished with very high precision to ensure minimal friction with the piston rings and seals, providing a perfect seal. The design of oil inlet and outlet ports, as well as channels related to the control system and valves, are also incorporated into the cylinder body or its connected parts.

-

Importance of Internal Quality of the Hydraulic Hammer Cylinder Any scratches, corrosion, or deformation on the inner surface of the hydraulic hammer cylinder can lead to oil leakage, pressure drop, loss of hammer power, and premature wear of piston seals. Using clean, high-quality hydraulic oil and timely filter replacement are crucial for maintaining cylinder health.

Part 2: The Hydraulic Hammer Anvil (Impact Ring)

-

What is the Anvil (or Impact Ring) in a Hydraulic Hammer? The hydraulic hammer anvil, sometimes also known as an impact ring, energy distributor, or even lower piston, is a highly resistant steel component located between the main piston and the tool (chisel) head. This part is the first recipient of the immense kinetic energy from the main piston.

-

The Key Role of the Anvil in Impact Energy Transfer The primary function of the hydraulic hammer anvil is the effective and safe transfer of impact energy from the piston to the tool. The anvil absorbs this energy and transmits it as a concentrated stress wave to the end of the tool, ultimately causing the target material to fracture. The anvil’s design must prevent energy loss and protect the piston and tool from damage due to direct and improper impacts.

-

Materials and Manufacturing Process of the Hydraulic Hammer Anvil The hydraulic hammer anvil is made from exceptionally hard and tough alloy steels that undergo very precise and complex forging and heat treatment processes. These processes ensure that the anvil can withstand extremely high contact stresses and repeated, severe impacts without permanent deformation or fracture. The contact surfaces of the anvil with the piston and tool are also machined and finished with high precision.

-

Importance of Anvil Condition and Fit Any wear, cracks, mushrooming of edges, or deformation in the hydraulic hammer anvil can lead to reduced energy transfer efficiency, increased harmful vibrations, and even damage to the piston or tool breakage. Regular inspection of the anvil and timely replacement if damage is observed are essential for maintaining optimal hammer performance.

Interaction and Coordination between Cylinder, Piston, and Anvil

The correct operation of a hydraulic hammer is the result of precise and engineered coordination between the cylinder, piston, anvil, and valve system. Clearances and dimensional tolerances between these parts are very important, and any deviation from standard values can disrupt the machine’s efficiency.

Maintenance and Inspections Related to Cylinder and Anvil

- Always use clean hydraulic oil as recommended by the manufacturer.

- Regularly replace hydraulic oil filters.

- Avoid operating the hammer under no-load conditions or with excessive pressure on the tool.

- Regularly visually inspect the hammer’s front head to check the condition of the anvil (if visible) and its surroundings.

- During periodic services and hammer disassembly, ensure a thorough inspection of the cylinder’s inner surface and the anvil’s working surfaces by a specialized technician.

Conclusion: The Vital Role of Cylinder and Anvil in the Efficiency of Hydraulic Hammers

The cylinder and anvil of hydraulic hammers, as two pivotal components, play an irreplaceable role in converting hydraulic energy into powerful demolition force. The manufacturing quality, raw materials, and proper maintenance of these two parts ensure the durability, power, and long-term productivity of the hydraulic hammer in the toughest projects.

Reviews

There are no reviews yet.