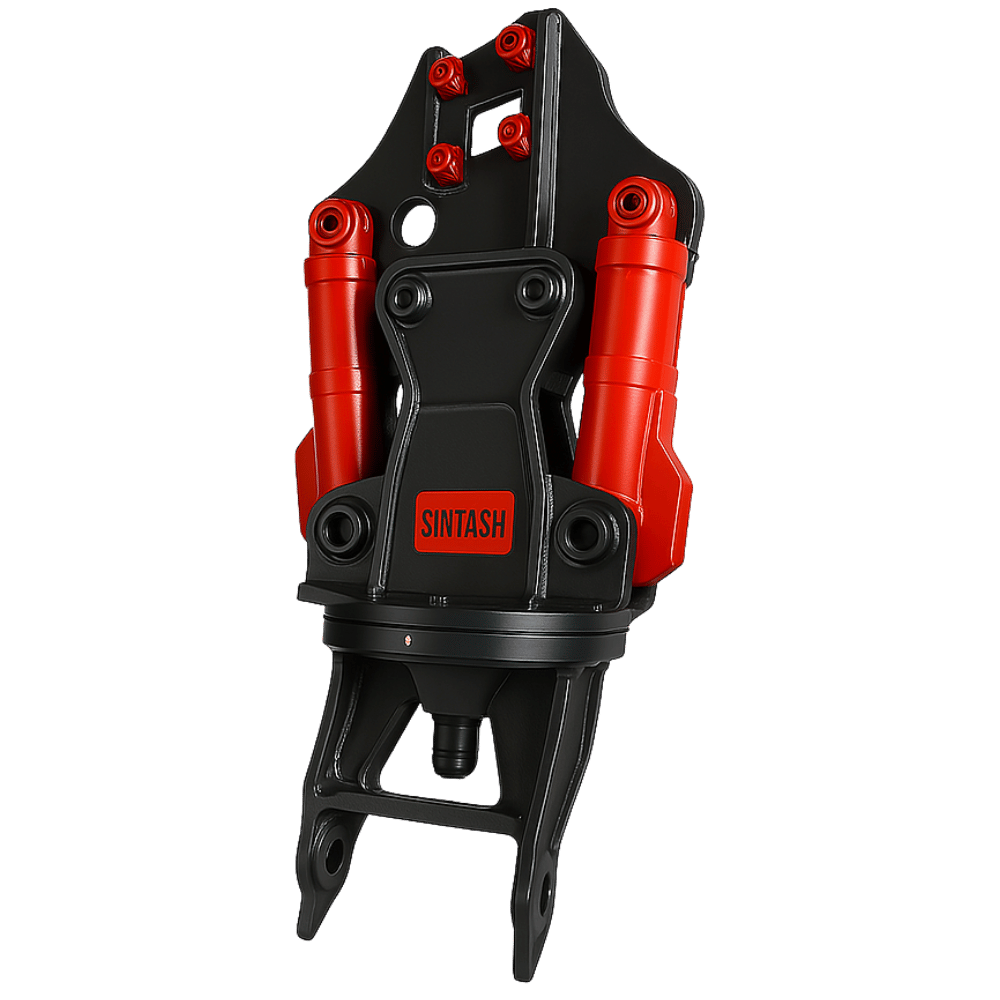

A hydraulic demolition jaw is an advanced and highly efficient attachment mounted on excavators, used for a wide range of demolition, recycling, and site preparation tasks. These powerful tools utilize the excavator’s hydraulic power to enable the crushing of concrete, cutting of steel structures, pulverizing of debris, and separation of materials with high speed, precision, and safety. The use of demolition jaws has revolutionized traditional, high-risk demolition methods, significantly contributing to increased productivity and reduced project costs.

Demolition jaws are designed and manufactured in various types for specialized applications, each with unique features and capabilities:

- Concrete Crushers/Crackers: These jaws feature powerful teeth and a specific design for the primary demolition of concrete structures such as walls, columns, foundations, and slabs.

- Pulverizers: Used for secondary demolition of concrete, reducing large concrete pieces into smaller debris. These jaws often also have the capability to separate rebar from concrete, facilitating the recycling process.

- Shears: These jaws act like giant scissors and are used for the precise and rapid cutting of various steel structures, I-beams, profiles, pipes, steel plates, and scrap metal.

- Multi-Processors: These advanced systems, with quick-change jaw sets, allow for multiple different demolition operations (such as crushing, shearing, and pulverizing) with a single base unit.

- Other Specialized Jaws: Such as wood shears, material handling jaws, etc.

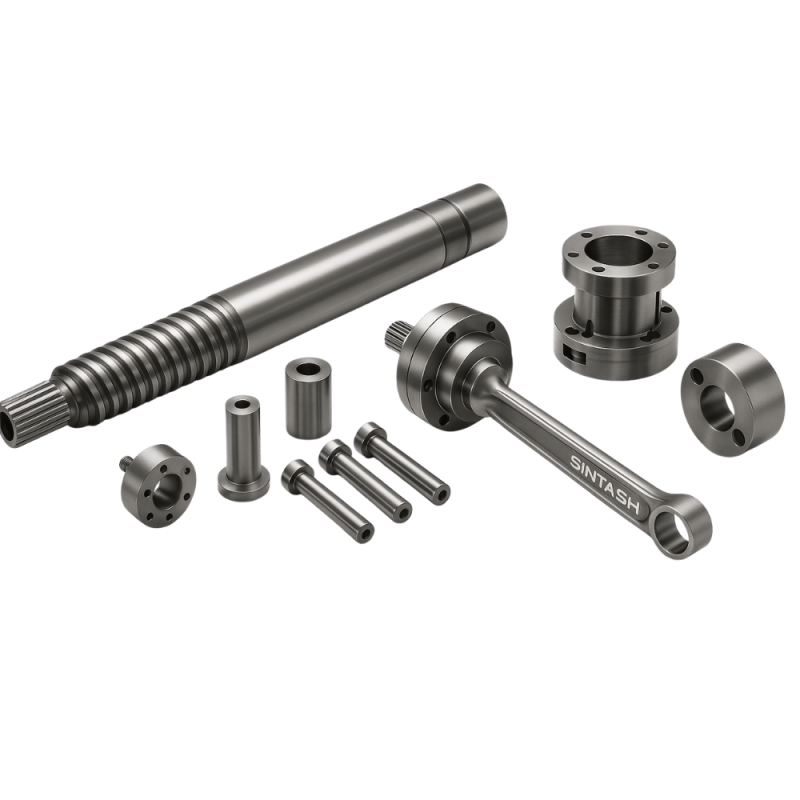

All high-quality hydraulic demolition jaws are constructed from highly wear-resistant and impact-resistant alloy steels. Powerful hydraulic cylinders, 360-degree rotation capability for better maneuverability, and replaceable blades and teeth are common features of these tools.

Key Benefits of Using Hydraulic Demolition Jaws:

- Significant increase in the speed and efficiency of demolition operations.

- Improved worksite safety by reducing the need for manual and high-risk methods.

- Reduced noise and dust pollution compared to traditional methods (in some models).

- On-site material processing and recycling capabilities.

- Reduction in debris volume and transportation/disposal costs.

- High adaptability to various projects and working conditions.

Selecting the appropriate type of demolition jaw depends on the type of structure, volume of work, and project objectives. These tools are an integral part of modern demolition, renovation, and recycling projects.

Reviews

There are no reviews yet.