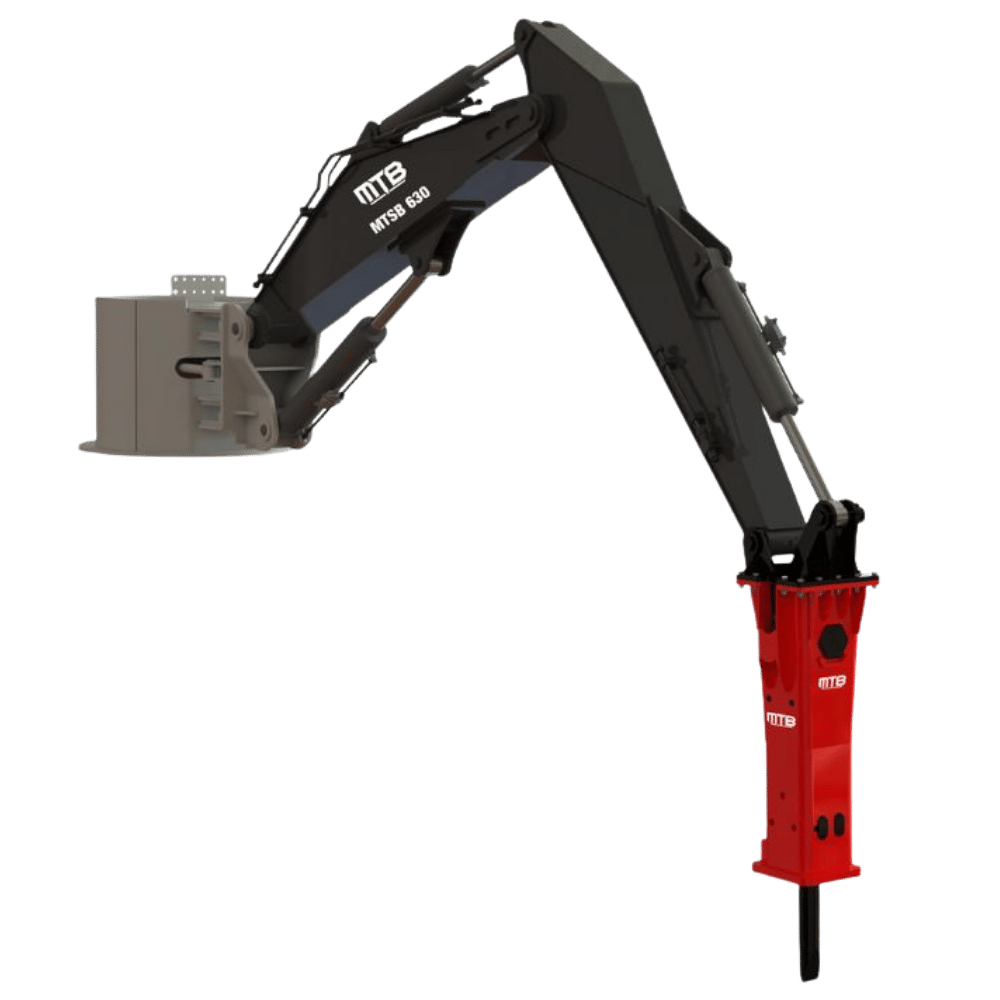

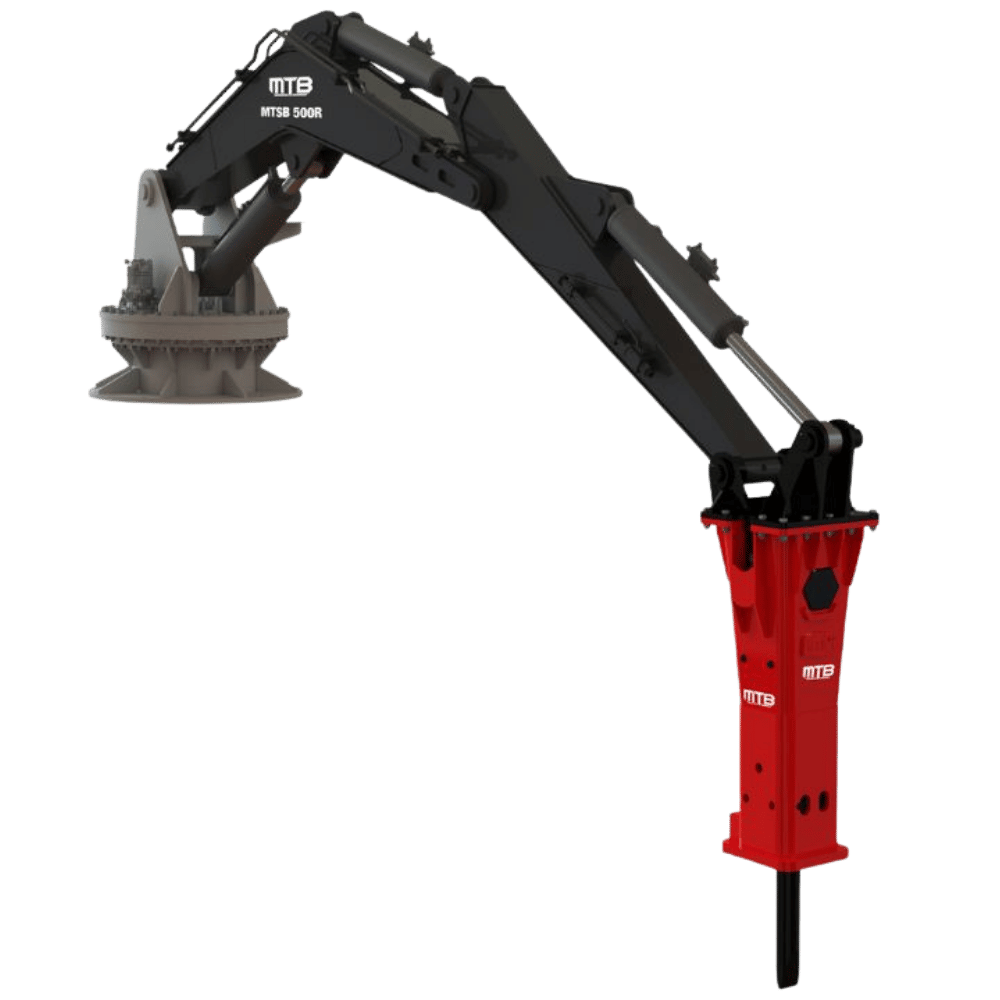

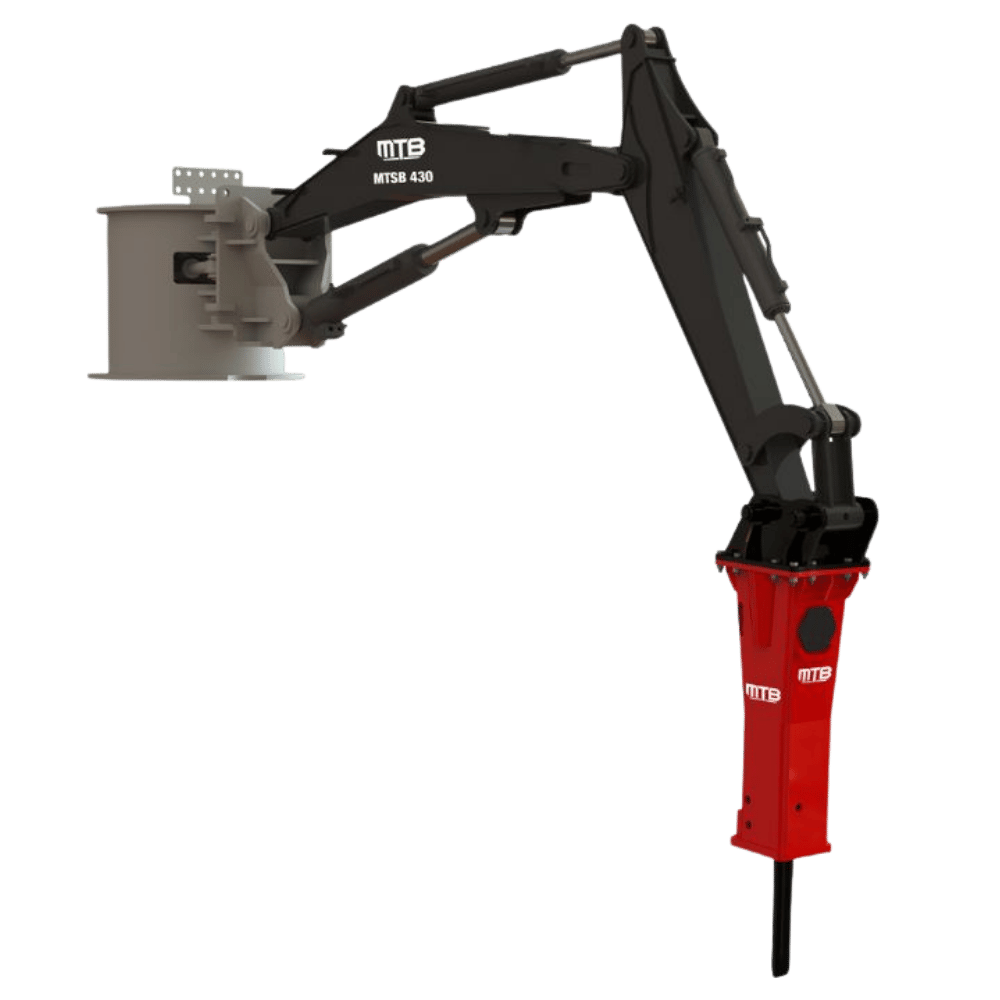

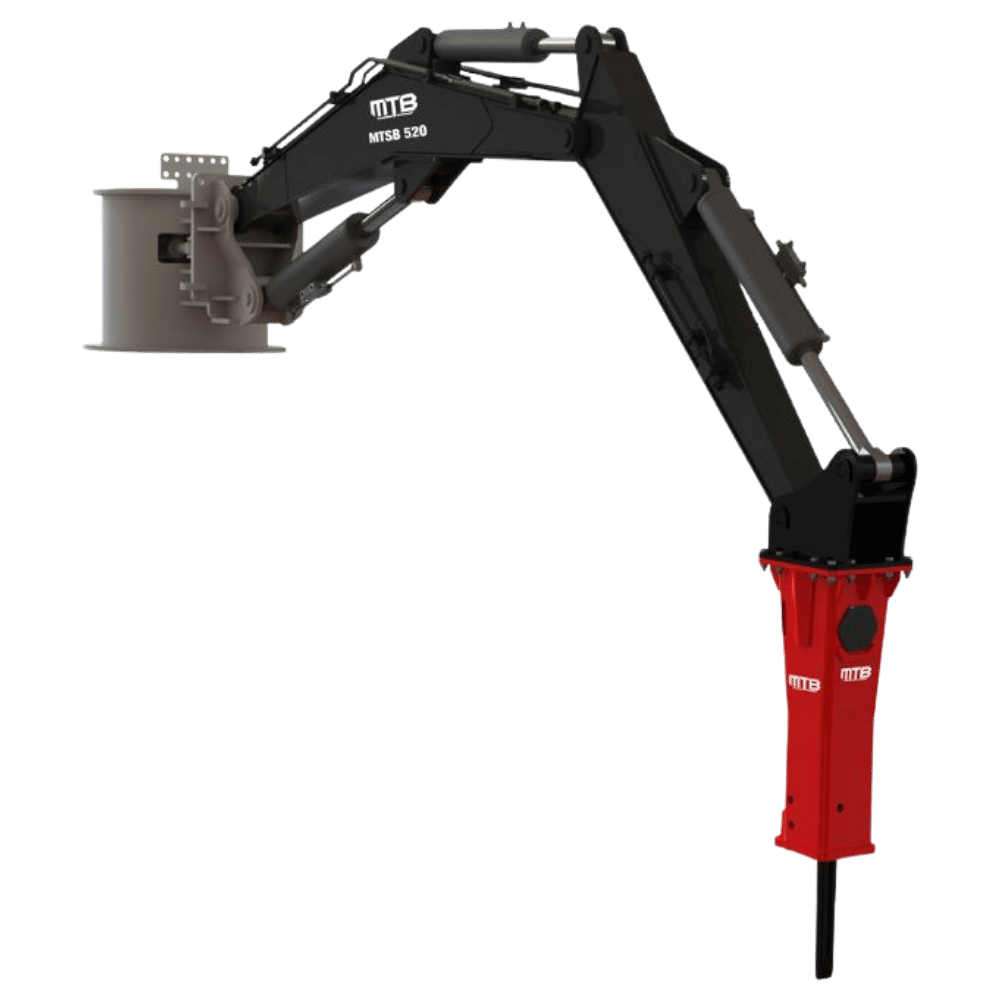

MTB stationary concrete placing booms offer an advanced and efficient engineering solution for the precise transfer and placement of concrete in large construction projects, high-rise buildings, bridges, dams, and other structures where accessing pouring points with conventional methods is difficult or time-consuming. These fixed Coded equipment, typically installed on the project’s foundation or main structure, enable the uniform pumping and distribution of concrete over a wide radius and at various heights, without the need for frequent relocation of ground concrete pumps or the use of heavy lifting equipment for each concreting phase.

The use of an MTB stationary placing boom significantly increases the speed of concrete pouring operations and helps reduce labor costs and ancillary equipment expenses. These systems, with their 360-degree rotation capability (or less, depending on the model and project requirements) and articulated arms providing extensive horizontal and vertical reach, direct the concrete precisely to the desired location. This placement accuracy prevents concrete wastage and improves the final quality of the structure.

MTB stationary concrete placing booms provide a high level of worksite safety, relying on robust design, the use of high-strength steel, and precise, reliable hydraulic systems. Modern control systems enable operators to manage boom movements with high precision. Sintash, by offering various models of MTB stationary concrete placing booms tailored to the needs and technical specifications of different projects, along with consulting, installation, and technical support services, assists you in selecting and optimally utilizing this equipment.

Key Features of MTB Stationary Concrete Placing Booms:

- Extensive Horizontal and Vertical Reach: Wide coverage of pouring points in tall and expansive structures.

- Significant Increase in Concrete Pouring Speed: Reducing project execution time and optimizing processes.

- Reduced Operational Costs: Savings on labor and ancillary equipment.

- High Precision in Concrete Placement: Preventing material wastage and enhancing structural quality.

- High Worksite Safety: Thanks to engineered design and advanced control systems.

- Reliable Performance and High Durability: Made from quality materials and standard components.

- Easier Installation and Operation Compared to Traditional Methods in Large Projects.

- Suitable for Various Construction, Industrial, and Infrastructure Projects.

For more information on the different models of MTB stationary concrete placing booms and to receive expert advice for selecting the best option for your project, please contact the specialists at Sintash.

Reviews

There are no reviews yet.