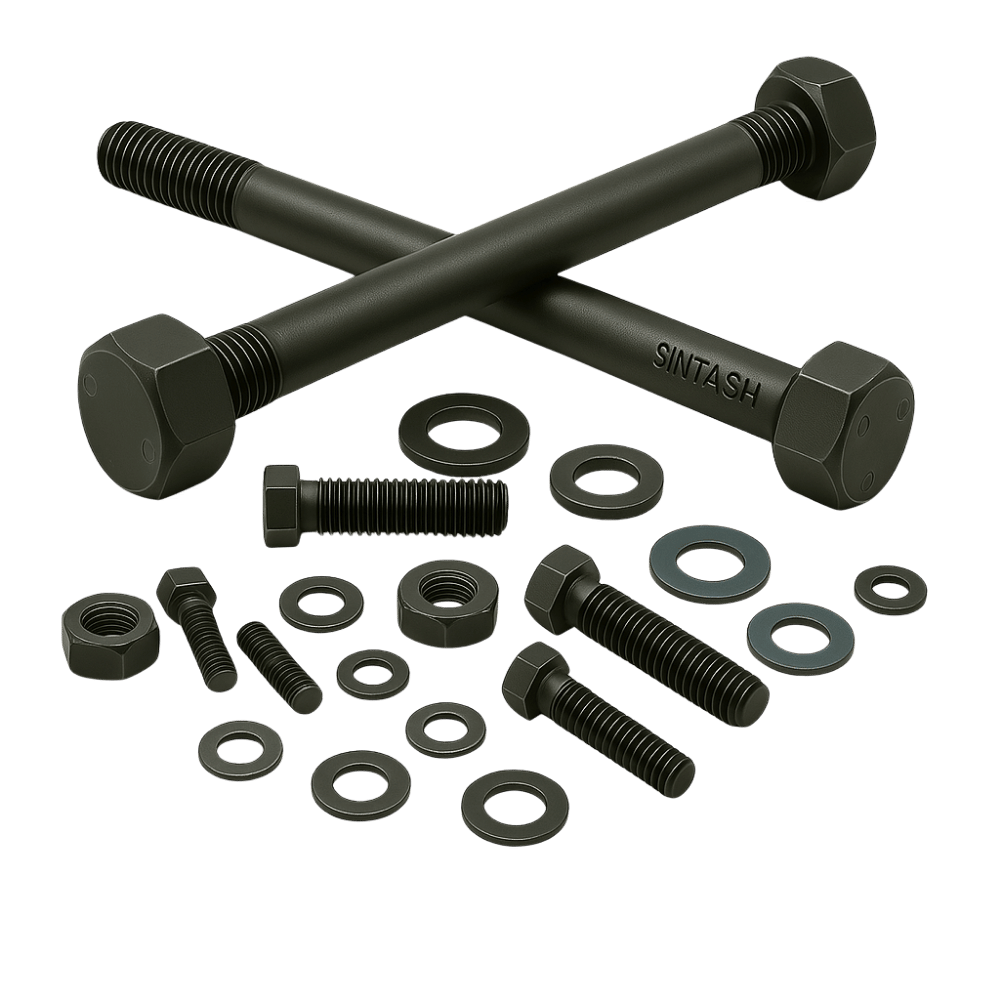

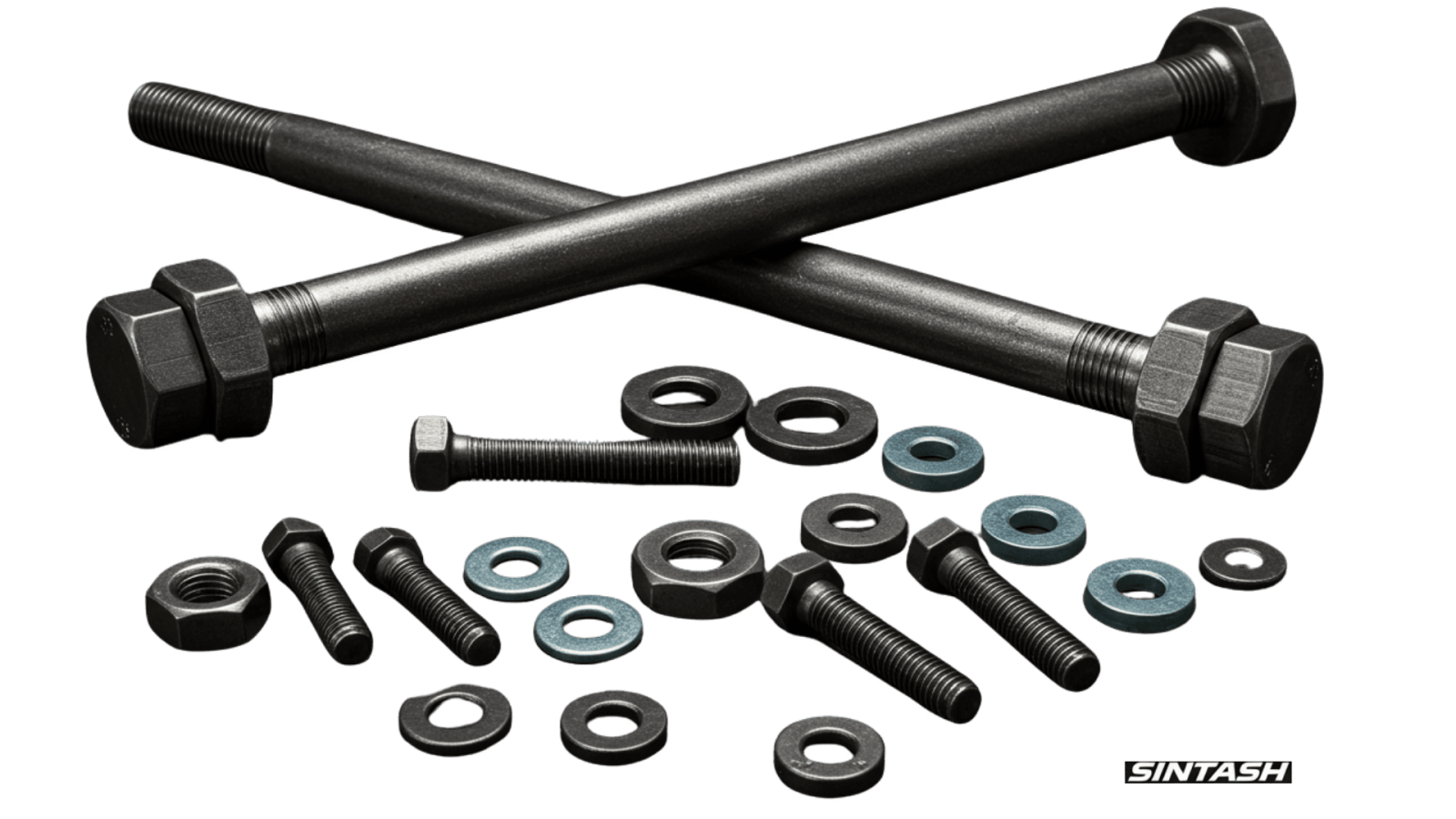

In the complex and high-stress structure of hydraulic hammers (breakers), bolted connections play a crucial role in maintaining the integrity and proper functioning of the equipment. Among these, tie rods and side bolts of hydraulic hammers are some of the most important fasteners, each undertaking specific tasks in holding different hammer components together and withstanding applied forces. A correct understanding of these bolts, their importance, and their maintenance is essential for users and technicians.

Tie Rods (Through Bolts) of Hydraulic Hammers

-

What is a Hydraulic Hammer Tie Rod and its Function? A hydraulic hammer tie rod, sometimes referred to as a through bolt, is a long, highly resistant threaded rod that passes through the main components of a hydraulic hammer, such as the back head, cylinder, and front head, and clamps these parts together by applying a very high compressive force. The primary function of tie rods is to maintain the structural integrity of the hammer against the enormous internal forces generated by piston movement and impacts, as well as severe operational vibrations. Typically, depending on the design and size, two or four of these bolts are used in each hydraulic hammer.

-

Material and Structural Features of Tie Rods Given the extremely high tensile and fatigue stresses that tie rods endure, they are made from special high-tensile strength alloy steel. These steels undergo precise heat treatment processes to achieve an optimal combination of strength and toughness (impact resistance). Their threads are precision-made, usually by rolling, which offers better fatigue resistance compared to machined threads. They may also have surface coatings for corrosion resistance.

-

Importance of Correct Pre-Tensioning (Torque) in Tie Rods One of the most critical aspects concerning hydraulic hammer tie rods is the application of the correct torque or pre-tensioning force during assembly. This pre-tensioning force must be exactly according to the hammer manufacturer’s specifications. Torque below the permissible limit leads to looseness between parts, reduced impact efficiency, and premature failure of bolts or damage to other components. Excessive torque can also cause permanent stretching of the bolt, thread damage, or even cracks in hammer parts.

-

Inspection and Maintenance of Hydraulic Hammer Tie Rods Regular inspection of tie rods for looseness, signs of corrosion, cracks, or any damage is essential. At intervals specified by the manufacturer, they should be checked and, if necessary, retorqued with a calibrated torque wrench. If any serious damage is observed, the bolt must be replaced.

Side Bolts of Hydraulic Hammers

-

Role and Application of Side Bolts in Hydraulic Hammers Side bolts of a hydraulic hammer refer to bolts typically used to attach auxiliary components or housing covers to the hammer. The role of these bolts can vary depending on the hammer design:

- In silenced or box-type hammers: Side bolts may be used to secure side plates or the outer casing to the main power cell. These plates help reduce noise and protect internal components.

- Attaching wear or protective parts: In some models, side bolts are used to attach wear plates or protective parts to the hammer body.

- Attaching accessories: For mounting certain accessories or brackets to the hammer body.

-

Types and Materials of Side Bolts The material of hydraulic hammer side bolts is also typically high-strength steel, but their strength level may differ from tie rods depending on their specific function. These bolts can also have corrosion-resistant coatings.

-

Important Notes Regarding Hydraulic Hammer Side Bolts Like tie rods, regular inspection of side bolts for looseness (due to vibrations) and overall condition is important. The tightening torque for these bolts should also comply with the manufacturer’s recommendations. In box-type hammers, the integrity and tightness of these bolts are effective in the proper functioning of the silencing system and preventing excessive housing vibrations.

Impact of Vibrations on Bolted Connections in Hydraulic Hammers

Due to their operational nature, hydraulic hammers generate very intense vibrations. These vibrations have a strong tendency to loosen bolted connections. This is why the use of high-quality bolts, correct torque application, and regular inspections are crucial for all tie rods and side bolts of hydraulic hammers.

Conclusion: The Importance of Strong Connections in the Performance and Safety of Hydraulic Hammers

Tie rods and side bolts of hydraulic hammers, although they may seem like simple components at first glance, play a fundamental and undeniable role in maintaining structural integrity, correct force transmission, preventing leaks, reducing unwanted vibrations, and ultimately, ensuring the safe and efficient operation of the hydraulic hammer. Adhering to the manufacturer’s instructions regarding these fasteners is a key part of the preventive maintenance program for any hydraulic hammer.

Reviews

There are no reviews yet.