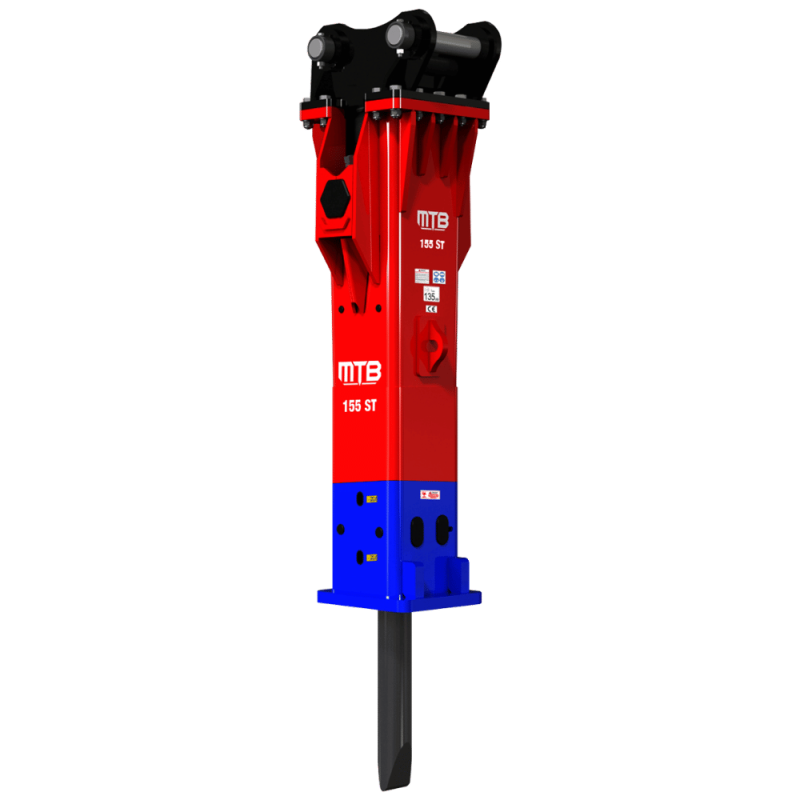

In the complex system of hydraulic hammers (breakers), the Tool Retainer for Hydraulic Hammers is one of the key components with the crucial task of securely and reliably holding the tool (chisel) in place. These parts, often designed as steel pins or special blocks (also colloquially referred to as “Loghmeh”), prevent the tool from being ejected during impact operations or when lifting the hammer, and also allow for easy tool replacement. The health and proper functioning of the tool retainer for hydraulic hammers are essential for operator safety and preventing damage to other hammer components.

Common Types of Tool Retainers and their in Hydraulic Hammers

Various mechanisms exist for retaining the tool in hydraulic hammers, but the most common are:

-

Tool Retainer Pins: The most common type of hydraulic hammer tool retainer involves the use of one or two hardened steel pins. These pins pass through holes provided in the front head of the hammer and engage with a special groove or recess on the tool shank. These pins (“Loghmeh”) lock the tool in place but allow it limited axial movement to transmit impact. These pins themselves have retainers like spring pins or small bolts to keep them in place.

-

Other Tool Retention Mechanisms: In some special designs, steel blocks, wedges, or different locking systems might be used as “Loghmeh” to retain the tool. Their overall function is similar to retainer pins, but they may differ in how they are installed and engage with the tool.

Functions and Vital Importance of Hydraulic Hammer Tool Retainers (Loghmeh)

Despite their apparent simplicity, hydraulic hammer tool retainers (Loghmeh) have very important functions:

-

Secure Tool Retention: The primary function is to prevent the tool from detaching and being ejected from the hammer during operation, which is a very serious safety hazard.

-

Ease of Tool Change: The design of tool retainers should allow the operator to easily and quickly replace the tool.

-

Absorbing Some Reaction Forces: Although not their primary function, these parts are also exposed to some reaction forces and vibrations.

Material and Structural Features of Tool Retainer “Loghmeh”

The “Loghmeh” or main components of hydraulic hammer tool retainers, especially pins, are made from high-quality alloy steels with the following characteristics:

- High Strength: To withstand shear and impact forces.

- Appropriate Hardness: For resistance to wear and deformation.

- Sufficient Toughness: To prevent brittle fracture under sudden impacts. These parts usually undergo precise heat treatment to achieve the desired mechanical properties.

Wear, Inspection, and Maintenance of Hydraulic Hammer Tool Retainers

Hydraulic hammer tool retainers, especially pins, are consumable parts and wear out over time.

-

Signs of Wear or Damage in Tool Retainers: Excessive wear on pin diameter, bending or deformation of pins, mushrooming of pinheads, cracking, and damage to the pin retainers themselves (like spring pins) are common signs of wear. Excessive play of the tool in its housing can also indicate wear on the tool retainer or hammer bushings.

-

Importance of Lubrication and Correct Installation: Proper lubrication of the tool shank (greasing) helps reduce wear between the tool, bushings, and also the tool retainer pins. When installing pins, ensure the area is clean and the pin retainers are correctly installed.

-

Regular Inspection and Timely Replacement: Regular inspection of the condition of tool retainers (Loghmeh) and their timely replacement upon observing damage or excessive wear are essential to prevent safety hazards and more costly damage to the hammer.

Safety Aspects Related to Tool Retainers

The proper functioning of tool retainers for hydraulic hammers is directly related to the safety of the operator and personnel at the worksite. Sudden failure or detachment of the tool can lead to very severe accidents. Therefore, thorough inspection and timely replacement of these parts should never be overlooked.

Conclusion: The Essential Role of Tool Retainers (Loghmeh) in the Safe and Effective Operation of Hydraulic Hammers

The tool retainer for hydraulic hammers is a small but vital component in the hydraulic hammer system. This part not only securely holds the working tool in place but also plays an important role in overall operational safety. Attention to the condition of these parts, regular inspection, and timely replacement are crucial parts of any hydraulic hammer’s maintenance program to ensure safe, reliable, and efficient operation.

Reviews

There are no reviews yet.